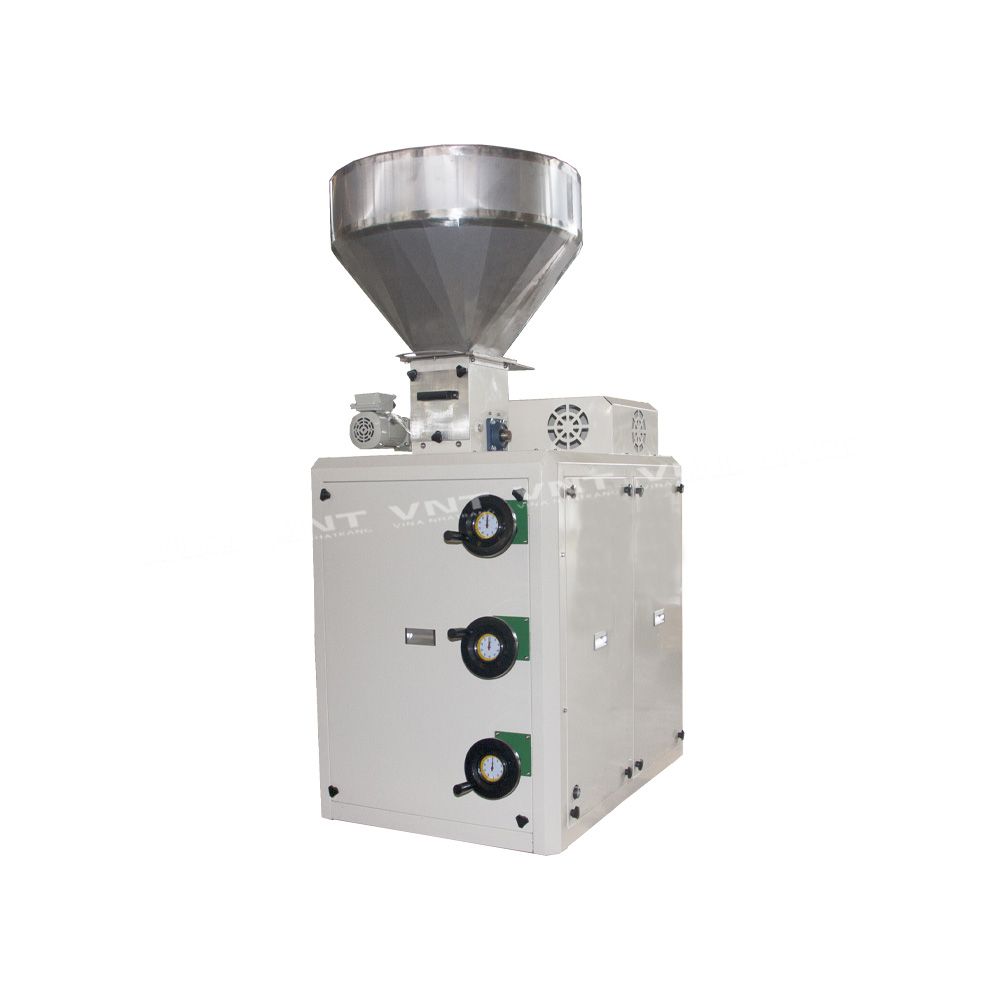

Industrial Coffee Mill Overview: Increase Efficiency and Top Quality

In the affordable landscape of coffee production, picking the appropriate industrial coffee mill plays a crucial duty in enhancing both performance and product high quality. Understanding the subtleties of various mill types and vital attributes-- such as customizable grind settings and durable building and construction-- can substantially affect the final flavor account of the coffee. The optimization of the grinding procedure, combined with thorough maintenance, is important for maintaining efficiency over time. As we check out these vital aspects, it ends up being evident that the ramifications prolong beyond simple equipment option, influencing general service success in manner ins which warrant closer evaluation.

Recognizing Mill Kinds

When picking a commercial coffee grinder, understanding the different kinds available is vital for optimizing both flavor removal and operational efficiency. The two primary kinds of mills are blade grinders and burr grinders. Blade mills make use of sharp blades that chop coffee beans into inconsistent sizes, bring about uneven removal and potentially undesirable tastes. While blade mills are frequently extra inexpensive and ideal for small operations, they are typically not advised for commercial use.

Inevitably, picking the ideal kind of grinder is important to preserving quality and effectiveness in coffee manufacturing, making it vital for organizations to purchase premium burr grinders for optimal outcomes.

Trick Functions to Think About

Choosing a commercial coffee mill requires careful consideration of a number of crucial attributes that can dramatically influence both performance and the total coffee experience. Among the primary aspects to assess is the grinding system. Burr grinders are generally preferred over blade mills, as they offer a consistent grind dimension, which is crucial for optimal extraction and taste.

An additional vital attribute is the mill's capability. Depending on the volume of coffee you require to procedure, select a model that can manage your demands without compromising rate or top quality. Additionally, take into consideration the grind settings used. A versatile mill with multiple setups enables you to customize the work dimension to different developing techniques, improving the coffee's taste profile.

The construction product likewise contributes in longevity and upkeep. Stainless steel parts commonly use longevity and are simpler to cleanse, which is crucial for preserving hygiene criteria. Examine the mill's noise level, specifically in a hectic café or manufacturing atmosphere, where too much noise can be disruptive. Spending in a mill that balances these features can considerably boost both functional performance and the quality of the coffee offered.

Optimizing Grinding Process

To accomplish the most effective outcomes in coffee prep work, maximizing the grinding process is vital. The work dimension dramatically influences removal, taste, and overall top quality of the brewed coffee. Different developing approaches call for certain grind sizes; for example, coffee requires a great work, while French press necessitates a crude appearance. Comprehending the partnership in between grind dimension and developing technique is the primary step in optimization.

In addition, checking the grinding speed can enhance the procedure. Slower grinding typically creates much less warmth, protecting fragile tastes and scents. On the other hand, quicker grinding may generate extreme heat, negatively influencing the coffee's top quality.

Upkeep and Treatment Tips

Proper maintenance and care of commercial coffee mills are important for guaranteeing optimal efficiency and durability. Normal cleaning is the structure of maintenance; deposit buildup can impact taste and grinding effectiveness. It is recommended to clean the grinder after each usage, wiping down the exterior and getting rid of any kind of coffee grounds from the burrs.

Additionally, evaluate the grinding burrs for deterioration. Boring burrs can jeopardize grind uniformity, so they should be replaced as needed. Industrial Coffee Grinder. Periodically adjusting the grinder is additionally vital, as this keeps the desired work dimension for different brewing techniques

Lubrication of moving parts need to be carried out according to the manufacturer's requirements, as this minimizes friction and prolongs the life of the devices. It is necessary to use food-grade lubricants to make certain safety and security and compliance with health and wellness guidelines.

Last but not least, maintain the grinder in a dry and secure atmosphere to prevent corrosion and deterioration. By adhering to these upkeep and care suggestions, drivers can boost the effectiveness of their industrial coffee grinders while ensuring premium outcome and expanded operational life.

Return on Financial Investment Analysis

Evaluating the return on financial investment (ROI) for commercial coffee grinders is critical for businesses looking for find out this here to optimize their coffee production capabilities. A detailed ROI analysis helps determine the financial feasibility of spending in high-grade grinders, permitting services to consider the initial costs against potential gains.

To carry out a comprehensive ROI evaluation, services need to take into consideration numerous essential factors. her comment is here First, evaluate the purchase price of the mill, including setup and any type of needed modifications to existing infrastructure. Next, determine functional costs, consisting of energy consumption, maintenance costs, and labor performance improvements. High-performance mills commonly cause decreased grinding time and boosted throughput, which can significantly improve efficiency.

In addition, take into consideration the impact on product high quality. Industrial Coffee Grinder. Superior mills produce a more consistent work dimension, which can enhance flavor profiles and customer contentment, eventually driving sales. By enhancing the high quality of the end product, companies can validate higher rates, leading to raised profits

Conclusion

In summary, an industrial coffee grinder plays an essential role in improving both performance and product high quality within coffee production. Ultimately, the calculated financial investment in a trustworthy grinder contributes dramatically to enhanced revenue and competitiveness in the coffee sector.

In the affordable landscape of coffee production, choosing the best industrial coffee mill plays a crucial function in enhancing both effectiveness and item top quality. The 2 main kinds of mills are blade mills and burr grinders. Within the burr grinder group, there are level burr grinders and cone-shaped burr mills, each with its advantages. Burr grinders are usually liked over blade grinders, as they offer a regular work size, which is click here for info essential for optimum removal and taste.

In recap, a commercial coffee grinder plays a crucial role in improving both efficiency and product top quality within coffee production.